Health and Medicine

Research

Disparities in sleep health and insomnia may begin at a young age

Black children were 2.6 times more likely to experience insomnia that begins in childhood and persists through young adulthood compared to white children

April 05, 2024

Latest News

Health and Medicine News RSS Feed

Q&A: Can weight loss drugs help in addiction treatment?

April 11, 2024

New role for bacterial enzyme in gut metabolism revealed

February 28, 2024

Improving efficiency, reliability of AI medical summarization tools

February 21, 2024

Heard on campus: Nikki Crowley on 30 years of neuroscience advances

February 13, 2024

How does Zika virus replicate and transmit from mother to fetus?

February 05, 2024

Undergraduate research may contribute to COVID-19 treatments

January 25, 2024

Foodborne-pathogen Listeria may hide from sanitizers in biofilms

January 24, 2024

Interactive screen use reduces sleep time in kids, researchers find

December 13, 2023

Bacteria's mucus maneuvers: Study reveals how snot facilitates infection

December 05, 2023

The golden rule may get a boost when teens feel connected to others

November 28, 2023

Study of sourdough starter microbiomes to boost bread quality and safety

November 21, 2023

Q&A: Modeling measles amidst a global disruption in vaccine supplies

November 16, 2023

Q&A: What can we do to prevent and control hypertension?

November 15, 2023

Understanding the barriers to taxing alcohol and tobacco in Nepal

November 13, 2023

Q&A: Can virtual reality help people eat a healthier diet?

November 10, 2023

NIH diversity grant to fund student’s 3D bioprinting research

November 08, 2023

Latest News

Health and Medicine News RSS Feed

Q&A: Can weight loss drugs help in addiction treatment?

April 11, 2024

New role for bacterial enzyme in gut metabolism revealed

February 28, 2024

Improving efficiency, reliability of AI medical summarization tools

February 21, 2024

Heard on campus: Nikki Crowley on 30 years of neuroscience advances

February 13, 2024

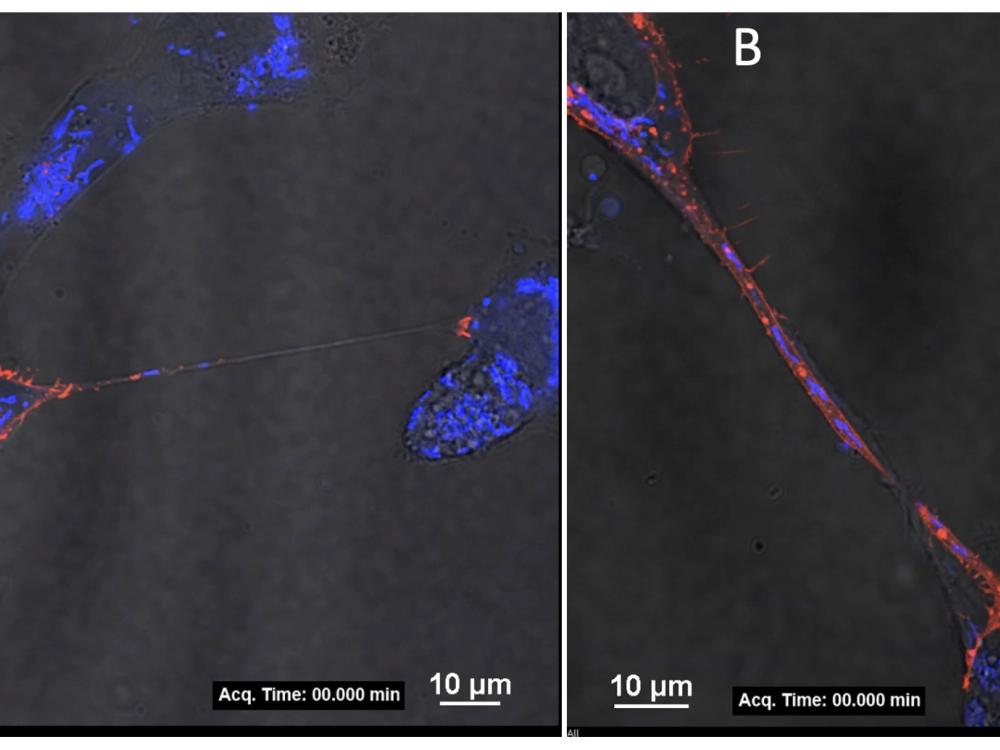

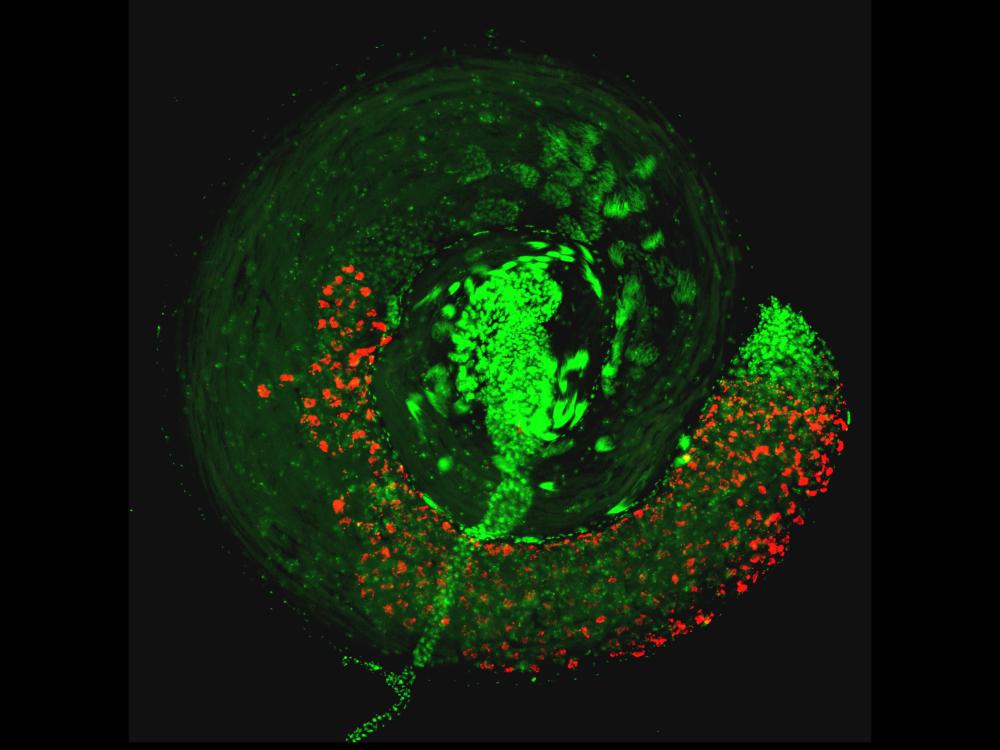

How does Zika virus replicate and transmit from mother to fetus?

February 05, 2024

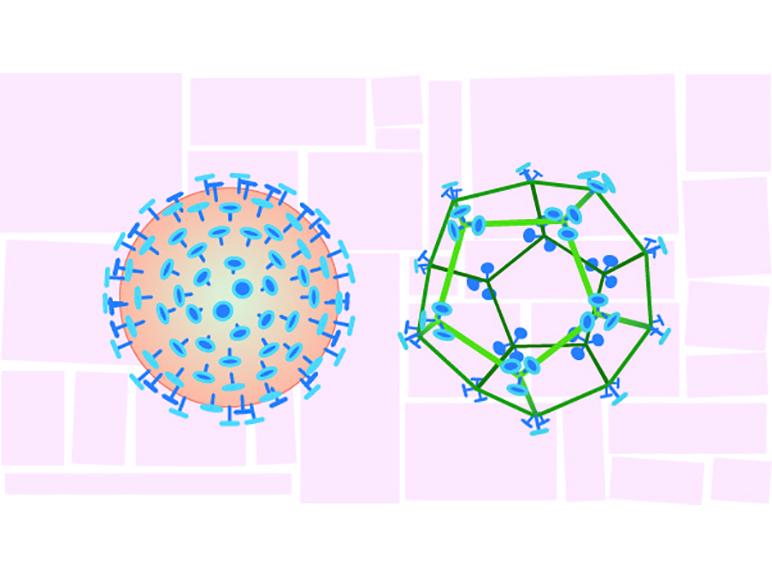

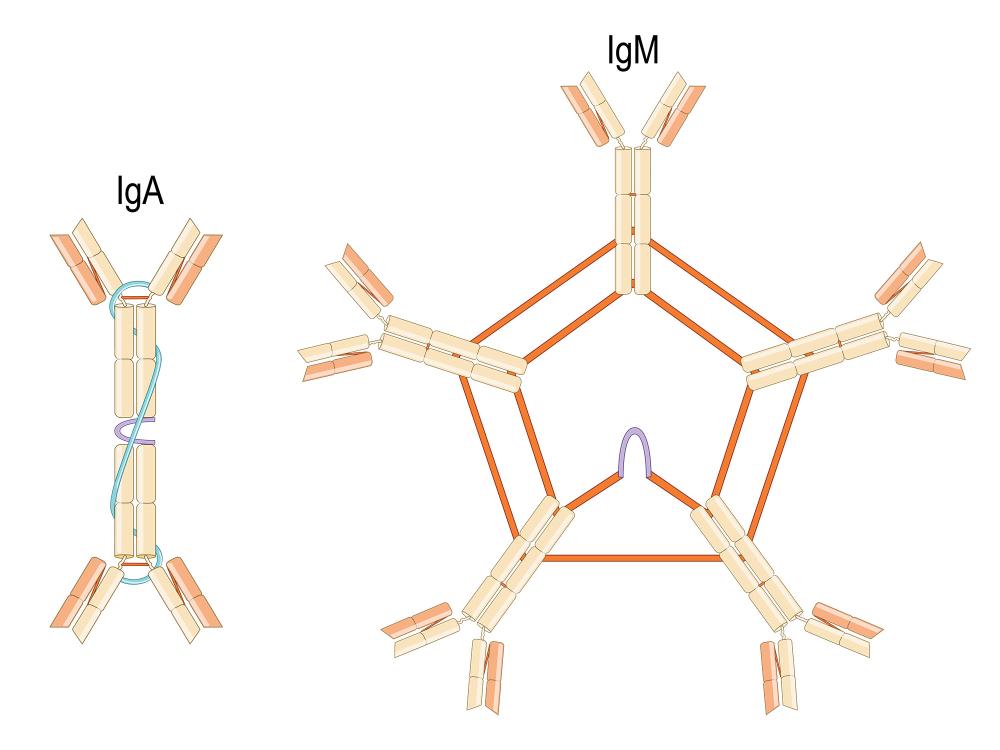

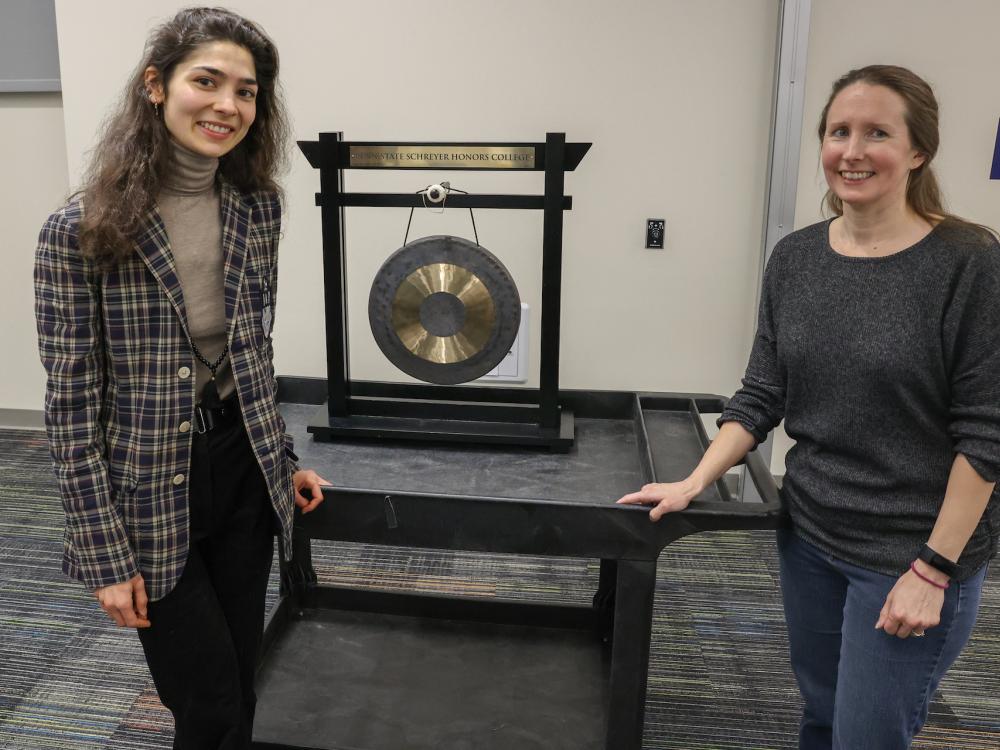

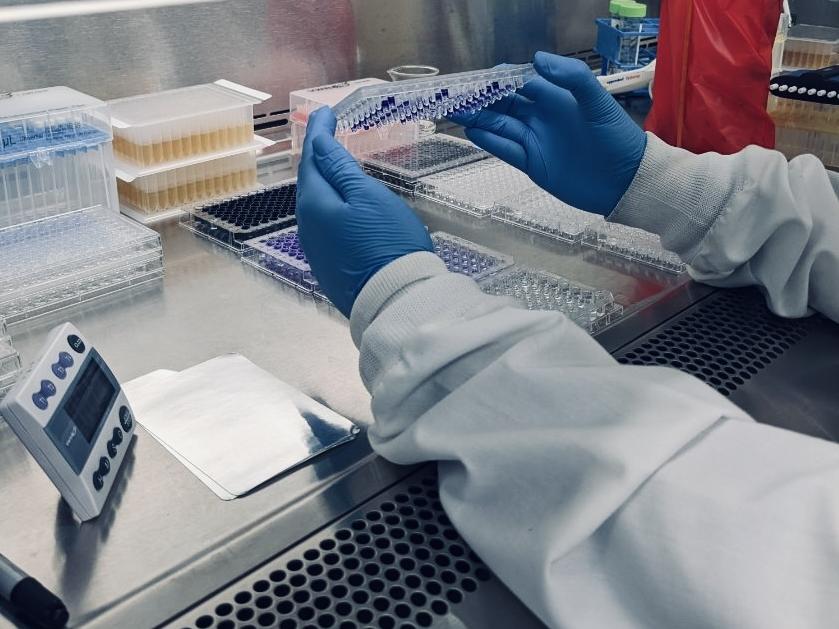

Undergraduate research may contribute to COVID-19 treatments

January 25, 2024

Foodborne-pathogen Listeria may hide from sanitizers in biofilms

January 24, 2024

Interactive screen use reduces sleep time in kids, researchers find

December 13, 2023

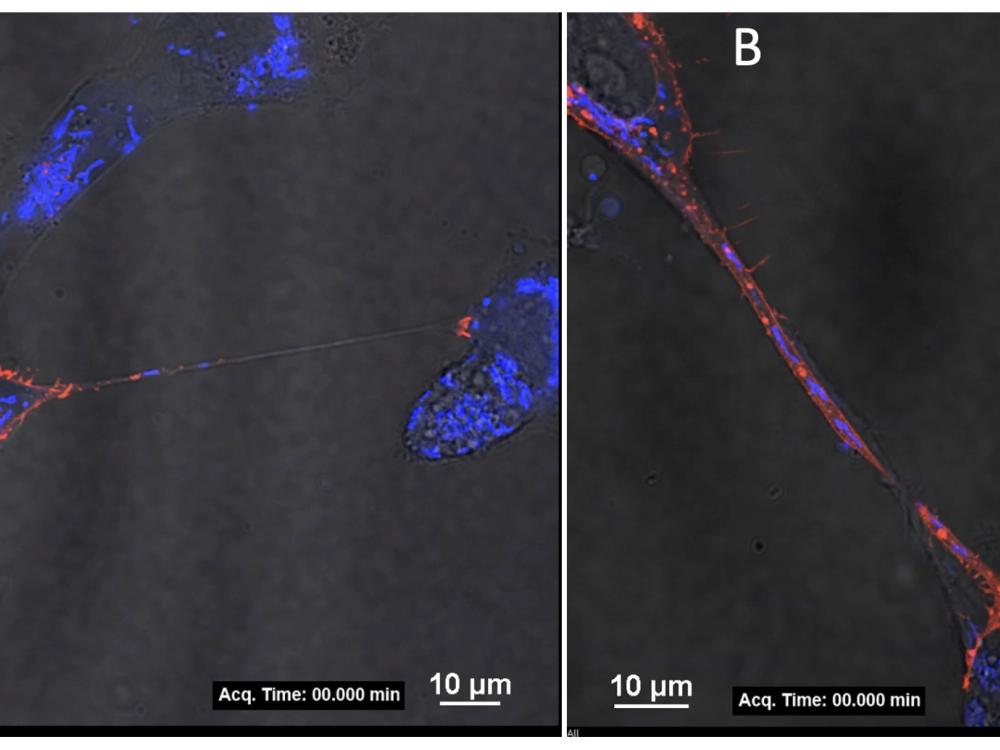

Bacteria's mucus maneuvers: Study reveals how snot facilitates infection

December 05, 2023

The golden rule may get a boost when teens feel connected to others

November 28, 2023

Study of sourdough starter microbiomes to boost bread quality and safety

November 21, 2023

Q&A: Modeling measles amidst a global disruption in vaccine supplies

November 16, 2023

Q&A: What can we do to prevent and control hypertension?

November 15, 2023

Understanding the barriers to taxing alcohol and tobacco in Nepal

November 13, 2023

Q&A: Can virtual reality help people eat a healthier diet?

November 10, 2023

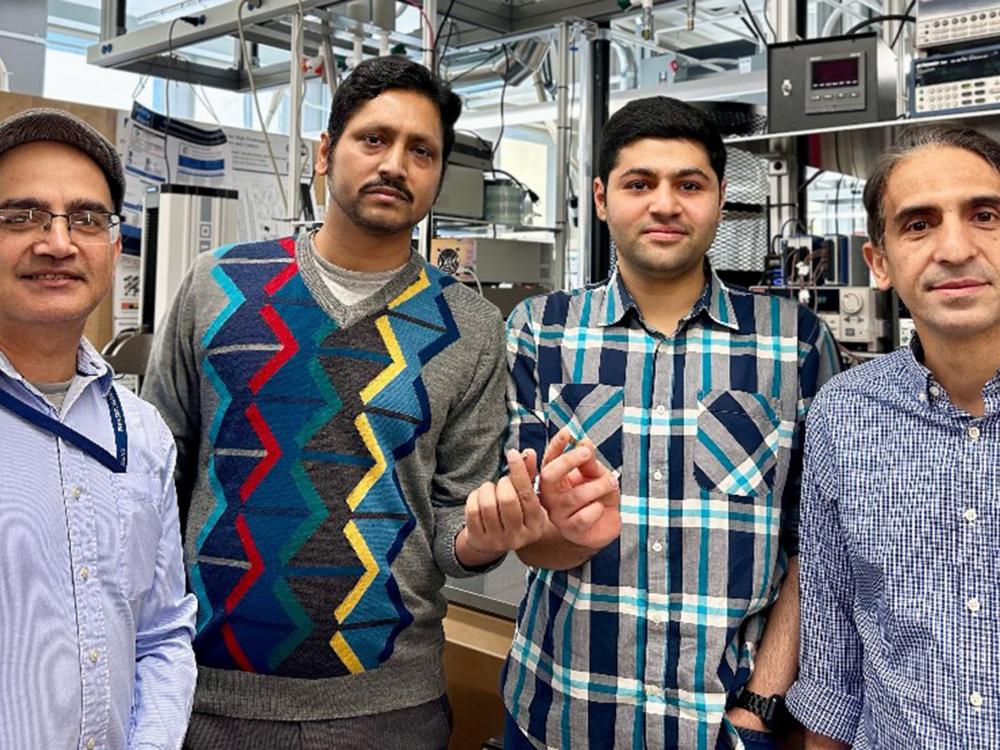

NIH diversity grant to fund student’s 3D bioprinting research

November 08, 2023

Get the news by email

Subscribe